Water is taken as effective medium for heat transfer and readily available too. Water dissipates heat evenly and transfers it outside in surroundings. Further cooling towers are divided into various categories like FRP cooling towers, industrial cooling towers, Pultruded cooling towers or air cooled system etc. You just have to choose right product that suits your project requirements the most.

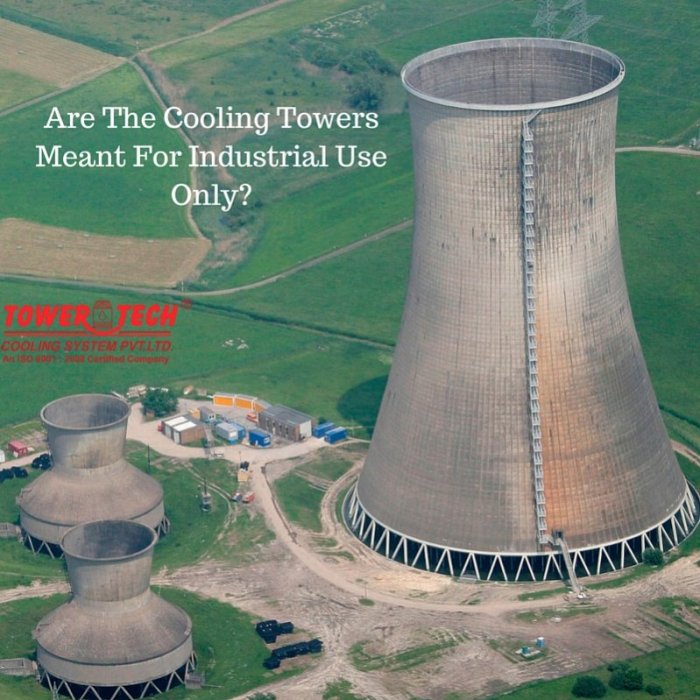

Today, cooling towers can be seen almost everywhere from food processing units to petrochemical areas and refineries etc. The applications don’t end here but they are good for commercial areas or public places too. These products should always be taken from reputed industrial cooling towers manufacturers in India that are efficient and cost effective both.

Cooling towers are designed with a single objective for proper heat transfer generated in plant. This will not only prevent overheating inside plant but protect employees too from unwanted damage. Cooling towers dissipate heat into surrounding and 100 percent environmental friendly product too. These are cost – effective considerations as recirculation is always expensive.

Today, cooling towers are used almost everywhere in global market. They are readily available and can be used in multiple configurations. They can be used as centralized system too that help in heat ejection into environment. In this way, safe temperature is maintained inside building and free from any health damage.

The only condition is that cooling towers should be designed carefully or industry specifications should also be taken into consideration. IT will help you in focusing on environmental problems in most natural way. You just have to find out best industrial cooling towers manufacturers in India that always work in your favor.

The next use of cooling towers is air conditioning inside commercial or industry establishments. They can be driven through motor and few are natural drafted fan assisted products.

Read More: